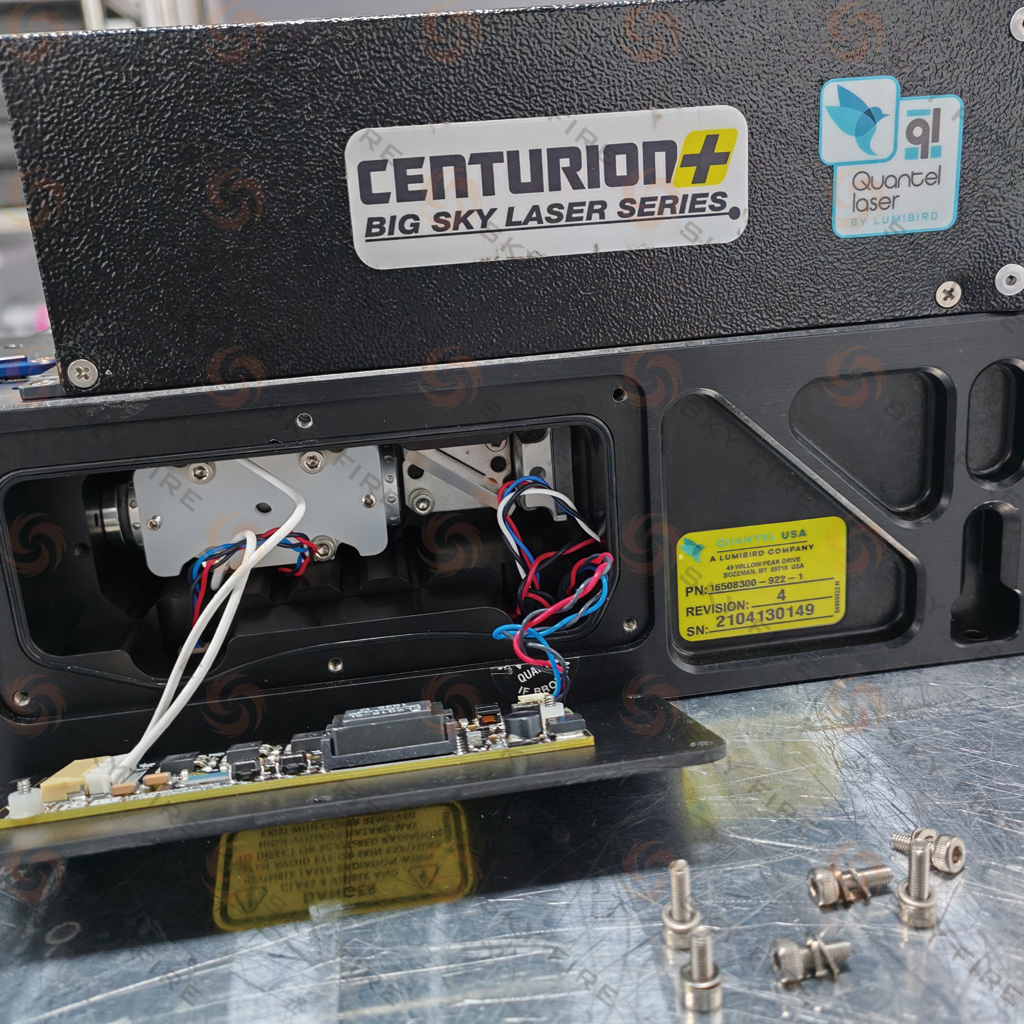

We provide expert solid-state laser repair services covering multiple brands including Quantel, Lumibird, and Coherent, helping you minimize downtime and reduce operational costs

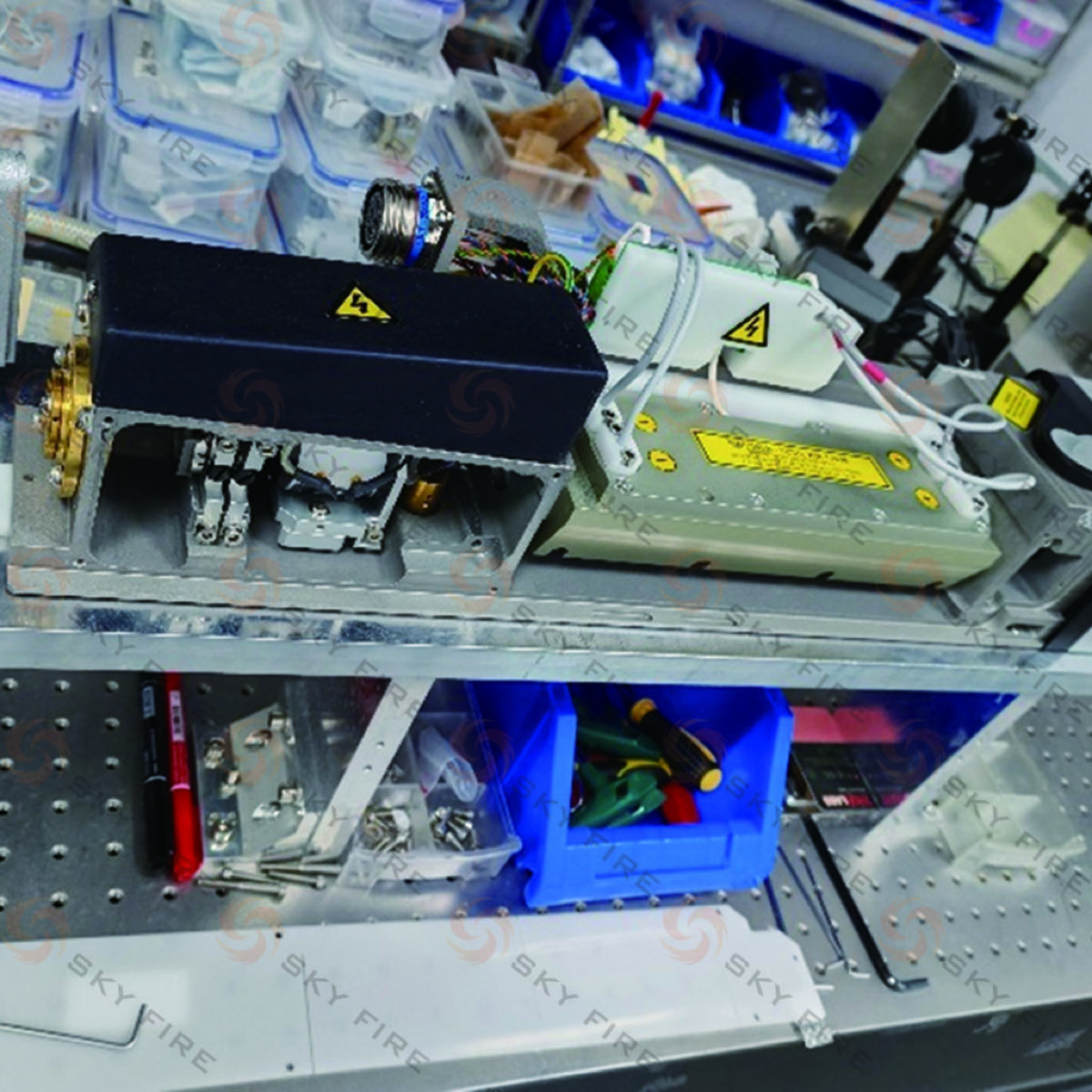

Our state-of-the-art repair laboratory is equipped with specialized testing instruments and tools. Expert engineers provide comprehensive diagnosis and precision repairs for solid-state lasers.

Advanced calibration platform ensures all repaired lasers meet original manufacturer specifications. Each system undergoes rigorous performance and stability testing.

"Their repair team diagnosed and fixed our Quantel CFR200 laser in just 5 days, when others quoted 2 weeks. Outstanding service!"

"We've been using SkyFire for all our Coherent Flare NX laser maintenance for over 3 years. Their knowledge and response time is unmatched."

"SkyFire helped us design a custom laser solution for our research facility. Their expertise across multiple laser types made this possible."

"When our Lumibird Q-smart850 failed during a critical experiment, SkyFire's emergency response team had it operational within 24 hours. Truly impressive."

"SkyFire's custom diode-pumped laser solution improved our manufacturing precision by 35% while reducing operational costs. A game-changer for our production line."

"After struggling with multiple vendors, we found SkyFire's technical expertise unparalleled. They implemented a comprehensive service plan that has kept our 8 Coherent Avia lasers operating flawlessly."

"The team at SkyFire designed a custom DPSS laser for our medical equipment that exceeded all specifications. Their deep understanding of medical applications gave us confidence throughout the project."

"SkyFire's preventative maintenance program has virtually eliminated downtime for our critical laser systems. Their technicians' expertise with both Quantel and Coherent systems is remarkable."

Comprehensive solutions for all your laser equipment needs

We provide comprehensive laser repair services covering various brands and models. With our extensive experience and professional expertise, we ensure your laser equipment quickly returns to optimal performance, minimizing downtime.

Inquire About Repairs

We design and manufacture high-performance lasers based on your specific application requirements. Working with leading brands like Quantel (Lumibird) and Coherent, we offer various types of advanced products including lamp-pumped and diode-pumped solid-state lasers to meet specialized needs across high-tech fields.

Explore Manufacturing CapabilitiesWatch our expert engineers at work on real laser repair projects

Join the Global Maker Community - Showcase Your DIY Fiber Laser Cutting Skills

Comprehensive repair and maintenance for various solid-state laser models from leading manufacturers

Application: Aerosol Radar

Type: Lamp-Pumped Solid-State

Application: Scientific Research

Type: Lamp-Pumped Solid-State

Application: Ozone/Temperature-Humidity Radar

Type: Lamp-Pumped Solid-State

Application: Mass Spectrometry

Type: Diode-Pumped Solid-State

Application: LCD Panel Repair

Type: Diode-Pumped Solid-State

Broad applications of lasers across multiple industries

Our laser solutions play a key role in the manufacturing process of display panels, covering full-process applications from exposure to repair and cutting, helping customers improve product yield and production efficiency.

We provide high-precision laser solutions for the semiconductor packaging industry, ensuring accuracy and efficiency in processes such as wafer cutting, contributing to quality improvement in semiconductor production.

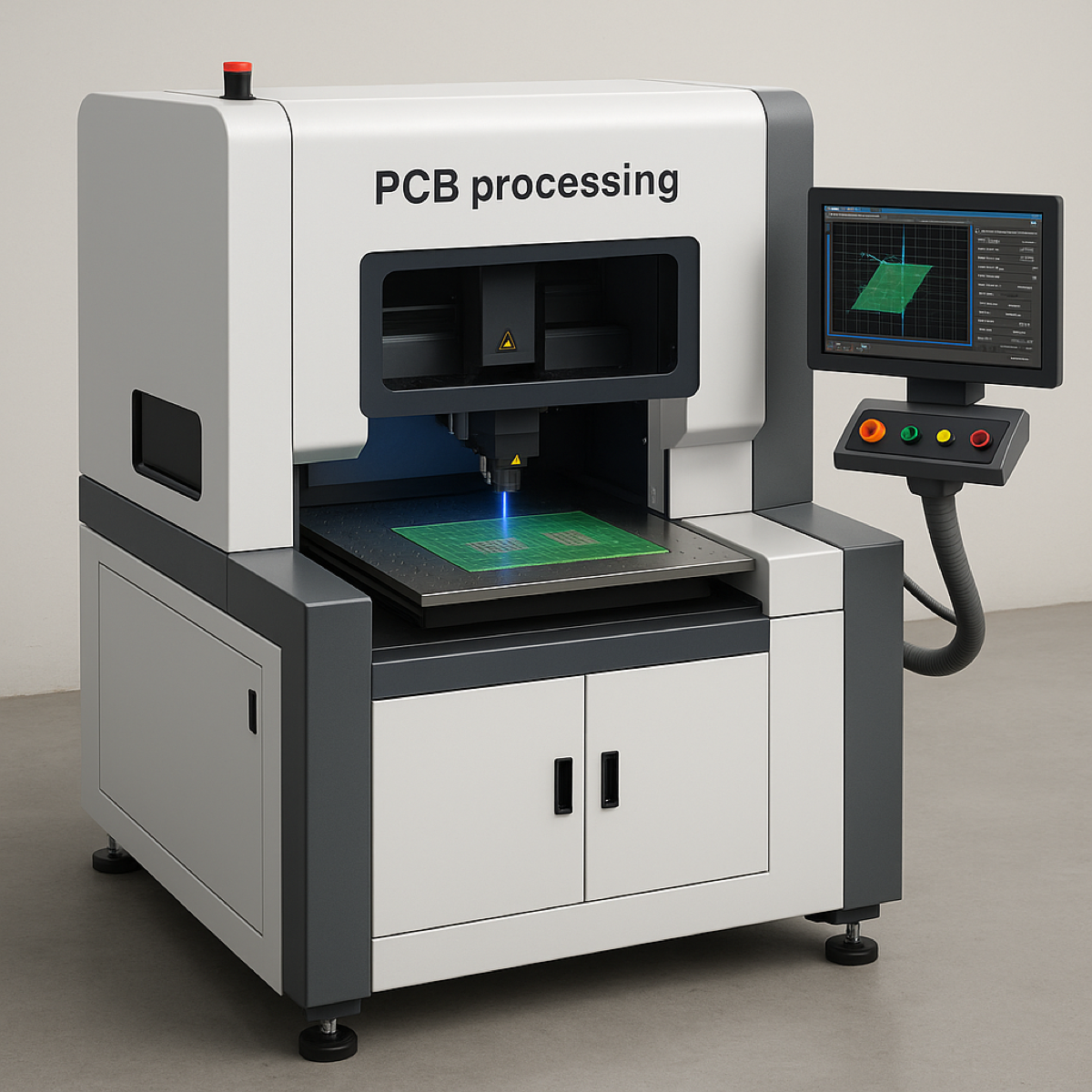

Our laser solutions excel in the field of PCB precision processing, especially in high-precision processes like laser drilling, ensuring micro-sized features and high-quality requirements.

We are committed to providing the most professional laser services and solutions

Years of laser industry experience with profound understanding of various laser principles and applications.

Familiar with and capable of handling mainstream laser brands including Quantel, Lumibird, and Coherent.

Serving high-demand fields including meteorology, scientific research, and industrial manufacturing.

Custom laser development based on specific requirements, providing optimized solutions.

Strict quality control processes ensuring excellent performance of repaired and manufactured lasers.

Efficient service team promptly responding to your needs, reducing equipment downtime.

Common questions about our laser repair and manufacturing services

We specialize in repairing various solid-state laser systems including lamp-pumped and diode-pumped lasers from major manufacturers like Quantel (Lumibird), Coherent, JDSU, and Amplitude. Our expertise covers models used in atmospheric research, mass spectrometry, display panel manufacturing, and PCB processing.

Repair time varies depending on the complexity of the issue and parts availability. Simple repairs typically take 5-10 business days, while more complex repairs may take 2-8 weeks. We provide emergency repair services for critical applications with 24-hour response time.

Yes, we provide a comprehensive warranty of at least 6 months on all repaired laser systems. Our warranty covers both parts and labor, and we ensure that all repaired systems meet or exceed original manufacturer specifications.

Absolutely! We offer custom laser design and manufacturing services based on your specific application requirements. Our team works closely with clients to develop optimized solutions for unique applications in research, industrial processing, and specialized measurement systems.

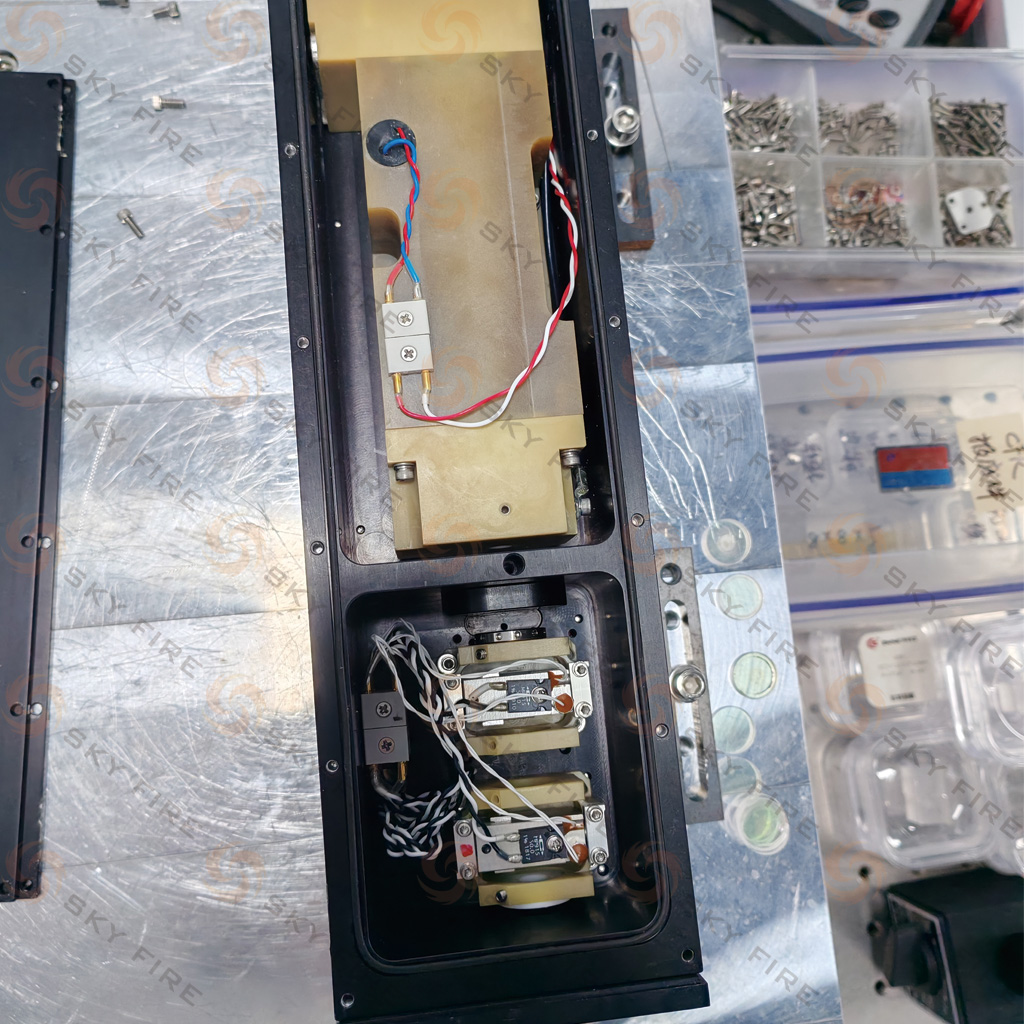

We provide comprehensive diagnostic services including power output measurement, beam quality analysis, optical alignment verification, and electronic system testing. Our advanced testing equipment ensures accurate fault identification and optimal repair strategies.

We only provide on-site services within China. For international customers, we are unable to provide on-site services.

Common failures include pump lamp degradation, optical misalignment, Q-switch malfunctions, power supply issues, cooling system problems, and crystal damage. We also frequently repair beam quality deterioration, unstable output power, and timing synchronization issues in pulsed systems.

Yes, we are proficient in both technologies. For lamp-pumped systems, we handle flashlamp replacement, cavity alignment, crystal replacement, mirror replacement, and thermal management maintenance. For diode-pumped lasers, we repair laser diode arrays, beam shaping optics, cavity alignment, crystal replacement, mirror replacement, and precision temperature control systems.

Absolutely! We maintain a rich inventory of legacy components and have the capability to manufacture custom replacement parts for some discontinued models. Our engineers have over 20 years of laser system maintenance experience and are familiar with various equipment from multiple manufacturers.

Our preventive maintenance includes regular optical cleaning, alignment verification, pump source inspection, cooling system maintenance, power calibration, and performance optimization. We offer scheduled maintenance contracts to prevent unexpected failures and extend equipment lifespan.

Safety is our top priority. Our technicians are certified in laser safety protocols, use appropriate protective equipment, and follow strict safety procedures. Our repair facility is equipped with proper ventilation, safety interlocks, and emergency shutdown systems.

Yes, we often recommend and implement performance upgrades during repairs. This includes upgrading to more efficient pump sources, improved cooling systems, better beam quality optics, or enhanced control electronics to improve reliability and performance.

We provide comprehensive documentation including detailed repair reports, performance test results, calibration certificates, parts replacement records, and maintenance recommendations. All documentation is traceable and meets industry quality standards.

Yes, we have extensive experience with custom-modified laser systems. Our engineers can reverse-engineer modifications, repair custom components, and maintain the integrity of specialized configurations while ensuring optimal performance.

For emergency repairs, we offer 24/7 technical support, expedited shipping, and priority scheduling. Our emergency response team can provide remote diagnostics, temporary solutions, and rush repair services to minimize critical downtime.

Yes, we repair and upgrade laser control systems including power supplies, timing controllers, temperature controllers, and user interfaces. We also provide software updates, parameter optimization, and integration with modern control systems.

Our repair center is equipped with advanced testing equipment including power meters, beam profilers, spectrum analyzers, oscilloscopes, thermal imaging cameras, fiber fusion splicers, autocorrelators, high-speed photodetectors, and high-precision alignment tools. This equipment ensures accurate fault diagnosis and verification of repair quality.

Yes, we maintain a selection of loaner laser systems for critical applications. Subject to availability, we can provide temporary replacement equipment to keep your operations running while your laser is being repaired.

We have extensive experience with international shipping of laser equipment. We handle all customs documentation, provide proper packaging for sensitive optical components, and work with specialized carriers experienced in handling precision instruments.

Our technicians are highly trained with backgrounds in optics, electronics, and laser physics. They receive ongoing training from manufacturer partners, hold relevant certifications, and have years of hands-on experience with various laser technologies and applications.

Whether you need laser repair services or custom laser manufacturing, our expert team is ready to help. Contact us for professional consultation and quotations.